-

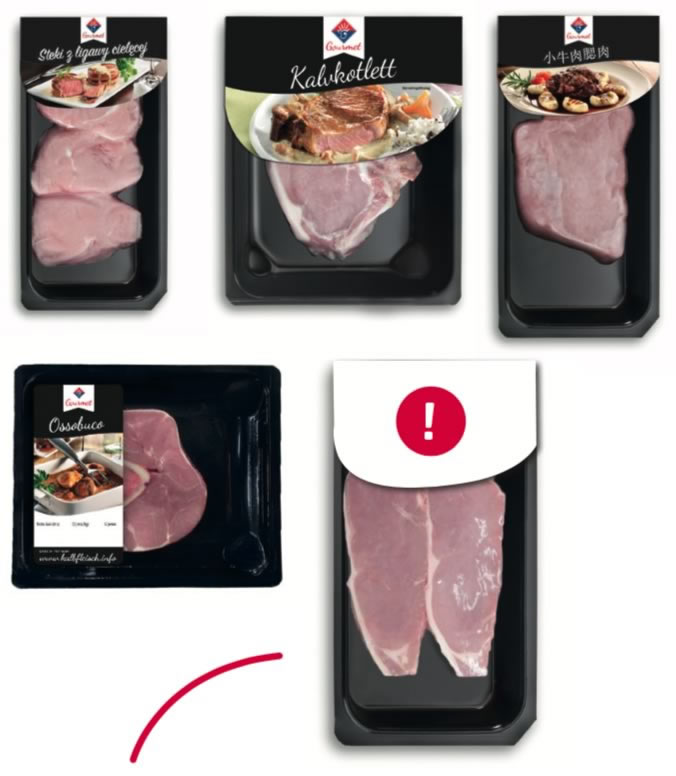

Gourmet skin packs make veal look much fresher and more appetizing.

-

The individual product range is now available - offering plain or marinated cuts.

Our Gourmet veal products look good, stay fresher for longer and are guaranteed to be best sellers in your refrigerated display unit. Skin-packed products look more appetizing.

The innovative skin-pack method is a new way to present products in an attractive way and ensure that they have a longer shelf life. After sealing the moulded bottom film of the tray, we seal the product with a special top film. This fits around the product like a second skin and keeps it securely in place, which prevents juices from escaping.

The materials used and the packaging process do not impair the quality of the product. The top film is heated and stretched only slightly and acts like a second skin without squashing the veal. It’s also possible to add an extra layer of top film on the skin pack to make the product stackable. The skin packs are also suitable for products with protruding parts such as bones. Juices are unable to escape from the veal and the cuts stay firmly in place in the packaging even when hung on a suspended rack or arranged on a slanted shelf. Products such as liver, sweetbreads and veal cheeks still look fresh even after several days.

Choose from a wide selection of skinpacked Gourmet products or ask about individual concepts.

‘Gourmet skin packs make veal look much fresher and more appetizing.’

What are the benefits?

- Gourmet products display veal at its best.

- Maximum durability, no loss of juices.

- Eye-catching and attractive packaging with individual design options.

- Transparent packaging has more appeal: the product looks much fresher and more appetizing.

- Foil seal is like a second skin: no bubbles and completely airtight.

- Product remains securely in place: suitable for suspended racks or slanted shelves.

- Skin packs are equally suitable for small or large products.

- Fully customizable for retailers, including labelling.

- Supported by online recipes.

- Extended shelf life.

- Individually portionable.

- Minimum waste.

Safety Guard is the VanDrie Group’s integrated quality system which assures food safety and animal welfare throughout the production chain. The responsible use of antibiotics and environmental management are also regulated through Safety Guard. The basis of Safety Guard is ISO 22000, the standard implemented throughout the VanDrie Group. Safety Guard has also been configured to meet the demands of customers worldwide. IFS and BRC are housed within Safety Guard. At the core of Safety Guard is the traceability system. The basis in every phase of the production process is the animal’s individual earmark, the ID code, which remains associated with the animal and the meat. Even when the meat is reduced further in the deboning plant, the ID code remains associated with each cut of meat.